AMPLIFY VOL. 37, NO. 10

This article explores how digital innovation can be used to transition to and operate large-scale electrified commercial vehicle fleets. It builds on prior research on digital sustainability, industry experience, and empirical illustrations.1,2

The Problem

The large-scale electrification of commercial vehicles is urgently needed. In the Netherlands in 2022, light and heavy commercial vehicles accounted for nearly 41% of CO2 emissions from road traffic while representing only 10% of all road vehicles.3,4

Between 2019 and 2022, CO2 emissions from these vehicles increased by 4% and 5.2%, respectively, mainly due to increased kilometers driven. In contrast, bus and coach CO2 emissions fell by 31.2% in the same period, largely due to government-mandated rapid electrification of city buses, with 27% of all city buses being electric by the end of 2022.5,6

The Obvious Solution

The logical conclusion is that the electrification of commercial vehicle fleets needs to be scaled up quickly. Replacing all vans and trucks with battery-electric equivalents and electrifying depots seems like a straightforward solution to reduce emissions and air pollution. Awesome, let’s go!

(Still need convincing that electric vehicles [EVs] are less damaging to the environment versus internal combustion engine [ICE] equivalents? I am happy to point you to the amazing work of Auke Hoekstra, program director at NEON research at Eindhoven University of Technology.7)

Unfortunately ...

Although necessary, the electrification of commercial vehicle fleets is not that simple. When not done right, it becomes expensive, complex, and ineffective. It is so new to the world that it makes AI hallucinate. When prompted to create “a depot for electric delivery vans with chargers and packages,” AI makes up some bizarre stuff (see Figure 1). It simply has no training data to make such an image.

Compared to city buses or passenger vehicles, commercial vehicle fleets encounter more constraints that affect their electrification and efficient operations. The constraints arise from factors such as electricity generation, storage, and access; EVs and charging infrastructure; and logistical and fleet operations.

To address these challenges, it’s essential to understand the implications these constraints have on operations, recognize the trade-offs and optimization points they introduce, and acknowledge that a suite of intelligent software solutions can help manage the trade-offs while capitalizing on opportunities for optimization. With this understanding, it’s possible to scale e-mobility operations to reduce the total cost of operation of a commercial fleet, accelerating the EV transition and sustainability impact.

Unpacking the Constraints

Electricity

Electrifying commercial vehicles at scale involves more than replacing a propulsion system and energy source. There’s a fundamental difference between using energy from fossil fuels and using electricity for mobility operations.

The energy transition impacts both the supply and demand sides of the electricity system, challenging the grid’s balance. Renewable energy sources are increasing on the supply side; on the demand side, processes previously powered by fossil fuels are being electrified.

Hydropower and biomass offer stable renewable energy but face geographical limitations and scalability issues, respectively. Solar and wind power, although scalable and cost-effective, present challenges due to their production volatility.

This volatility makes grid balancing from the supply side more difficult, increasing the importance of using dynamic electricity pricing to incentivize demand at appropriate times. Consequently, electricity prices have become more volatile, with variations of up to 1,000% in a day in the Netherlands. Negative prices are also possible, with 105 instances of hourly negative prices in 2023, up from 70 in 2021.8

On the demand side, the electrification of various activities (heating, cooking, production processes, mobility) is changing the predictability of electricity needs. For instance, any location with electricity can become a charging point, creating a totally new source of electricity demand.

These changes make it challenging for grid operators to maintain balance. The transition requires new strategies for managing supply volatility and unpredictable demand patterns, emphasizing the need for flexible, responsive electricity systems.

Implications for E-Mobility at Scale

Using electricity to scale commercial vehicle mobility operations has several important implications. First, demand for electricity must be balanced with supply in terms of quantity, location, and timing. The ability to predict in advance how much energy will be needed, as well as where and when it will be required, simplifies the process of securing the necessary supply, especially since a fleet will not have access to unlimited electric energy. Additionally, increasing access to electric energy is not a quick process; in some cases, it will not be feasible. Ideally, EV fleets will be able to take advantage of fluctuating electricity prices. Furthermore, charging can occur at a wider range of locations compared to traditional fueling stations.

EVs & Charging

The second set of constraints impacting efficient fleet electrification comes from EVs and charging. To understand these challenges, it’s useful to contrast them with the ICE ecosystem.

The ICE Age

Over the past century, the ICE vehicle ecosystem has been refined and optimized. There is universal compatibility between vehicles and fuel pumps, ensuring that fueling is consistent across stations. Fueling speeds are uniform, and widely accepted payment options are available at all stations. The extensive distribution of fuel stations significantly reduces the risk of running out of fuel, and price variations between stations are relatively small, typically 0% to 5%. Decades of fleet operator experience have led to predictable outcomes in terms of fuel consumption, maintenance, vehicle capabilities, operating costs, and residual values.

EV Variables

With battery EVs, established norms and standardized practices are evolving. We are just beginning to adopt this technology and need to invent, create, and optimize its ecosystems. In doing so, many variables have an operational impact on EVs. We must take these on board and design for them.

The electrification of commercial fleets introduces several complexities related to charging infrastructure, starting with plug types. Multiple incompatible plug types exist (e.g., Combined Charging System [CCS], CHAdeMO [charge for moving], Type 2, North American Charging Standard [NACS], and Megawatt Charging System [MCS]). Although there has been some regional convergence, it’s essential to know which chargers are compatible with your fleet to ensure successful charging.

Charge power also varies across chargers, directly impacting charge times. To avoid unnecessary time and financial costs, it is crucial to identify in advance the optimal chargers for each vehicle. Although charging takes longer than refueling, it can be done wherever electricity is available, enabling an “always charging” approach. Charging is most efficient when combined with other activities to minimize downtime.

Another challenge is availability: busy periods can lead to bottlenecks at charging stations. Access to reliable, predictive availability data helps drivers and fleet operators avoid wasting time waiting for chargers. Payment methods also vary across charging stations, and not all charge cards are universally accepted. Understanding which chargers support which payment methods is key to a smooth charging process.

Unlike traditional fueling, where prices are relatively stable, charging costs are highly volatile, making it important for fleet managers to carefully select charging locations to balance time and cost. Finally, an EV’s range is not fixed. It depends on factors such as vehicle specifications, driving conditions, environmental factors, auxiliary systems, and battery type.

Implications for E-Mobility at Scale

These variables introduce complex considerations around charging infrastructure, vehicle capabilities, investments, and operational planning. Key areas to focus on include:

-

Compatibility — ensuring vehicles and charging stations have matching plug types and power capabilities

-

Charging strategy — balancing slow and fast charging options to optimize time and cost-efficiency

-

Payment and pricing — navigating the complex landscape of electricity pricing, charge providers, payment methods, and pricing structures

-

Range management — accounting for various factors affecting EV range to plan charging and routes effectively

-

Fleet optimization — considering vehicle specifications, charging infrastructure, and operational needs to maximize efficiency and minimize total cost of ownership

By addressing these aspects, fleet operators can successfully transition to EVs while maintaining operational efficiency and cost-effectiveness.

Logistics & Fleet Operations

The logistics, distribution, and supply chain ecosystem aims to move goods from manufacturers to consumers. It is highly intertwined and operates at low margins, leaving little room for errors or costly experiments during the transition to electrified fleets.

The logistics ecosystem is generally divided into three key stages: (1) the first mile, which involves collecting goods from producers or manufacturers; (2) the middle mile, which focuses on transporting goods between local hubs and regional distribution centers; and (3) the last mile, which entails delivering goods to the end consumer.

Each stage has unique challenges. In the first mile, ensuring physical accuracy in product selection and packaging, maintaining precise data and documentation, and having adequate infrastructure and technology are critical. The middle mile faces challenges related to long-distance international coordination and managing unforeseen disruptions.

The last mile is particularly complex. It involves meeting customer expectations for fast (and often free) shipping while managing high costs, which can account for up to 53% of total shipping expenses.9 Other challenges include navigating urban congestion, optimizing delivery routes, handling returns and failed deliveries, providing flexible delivery options, and addressing sustainability concerns.

Fragmentation

The last-mile delivery industry is highly fragmented, particularly in the Netherlands.10,11 Although there are well-known brand names, most deliveries are handled by networks of subcontractors and sub-subcontractors. Most fleet operators have relatively few vehicles (10-40). The first- and mid-mile sectors are even more fragmented, with 90% of companies operating fewer than 10 trucks and only 1% operating more than 50.12

Service fleets, such as those used by construction workers, plumbers, and electricians, also rely on commercial vehicles. These drivers often take vehicles home, using hubs primarily for restocking equipment and onboarding crews.

Last-mile delivery and service fleets face the most pressure to electrify due to their urban presence. These fleets primarily use light- and medium-duty vehicles, for which many electric options are available. First- and mid-mile operations, which rely on trucks, are seeing slower adoption of electric variants as megawatt charging infrastructure develops.

Charging strategies vary based on operational needs. Last-mile delivery vehicles are typically parked overnight at logistical hubs or depots; service fleet vehicles are often taken home by drivers. For trucks, key considerations include daily travel distances and whether vehicles park overnight at depots or truck stops for long-distance operations.

These factors significantly influence charging requirements, vehicle ranges, available charging time slots, and resulting electric power needs. The fragmentation in the market makes change complicated. Small players lack the resources (financial and technical) to coordinate, develop, and introduce new processes and technology that require integration with other parts of an ecosystem.

The transition to e-mobility in logistics and fleet operations presents unique challenges for each segment. Successful electrification strategies must consider the specific operational needs, infrastructure requirements, and charging patterns of various fleet types while addressing the broader issues of fragmentation and sustainability in the industry.

The Working Solution

How do we get to seamless, scalable, and cost-effective commercial EV operations? We do it by: (1) accepting that the requirements, constraints, and dynamics mentioned above are (like your fleet) part of a new charge-drive-logistics ecosystem; (2) understanding that transitioning to and operating in this new ecosystem has different optimization points that must be designed for; and (3) realizing that simplistic, like-for-like hardware replacement of ICE vehicles with EVs and chargers won’t cut it.

We need intelligent, flexible digital solutions to bridge the gaps between electricity, EVs, and logistics. These solutions consist of building blocks that must be integrated with one another, the chargers, and EVs. The aim of the hardware/software combination is to optimize the two primary states of a fleet: being driven (on a mobility mission) and being on downtime.

In a moment, we’ll examine the software building blocks and describe their functions. We’ll also discuss the most important implementation strategies, allowing you to efficiently scale and future-proof an electrified fleet. But first, we need to take a step back and discuss the most important design mantra for any fleet electrification — the principle that overarches all.

The Mantra: Match Supply & Demand

As is the case with anything you want to scale in “electricity land,” you must match supply and demand. In the case of e-mobility at scale, you must match charge supply with charge demand. Charge supply is a fleet’s access to actual charge and battery capacity. Charge demand is the amount of energy a fleet needs for its operations.

The Typical EV Pilot

Most fleets don’t follow this mantra. They order a small number of EVs as pilots, often with large battery packs, install a charger for each vehicle, and charge them fully overnight. These vehicles are then deployed on short, predictable runs.

The issue is that this approach doesn’t scale. A like-for-like replacement results in overinvestment, potentially leading to higher total cost of ownership and loss of competitive position.

A Balanced Electrification Strategy

The goal should be to efficiently grow an electrified fleet while balancing charge demand with supply. This involves having the right number of chargers with high utilization, understanding and managing grid connection limitations, and optimizing charging based on fluctuating electricity prices. It also requires investing in vehicles and battery capacities that are fit for purpose: electrifying all routes, operating at a lower total cost of ownership, and leveraging electrification as a competitive advantage.

Balancing Charge Demand & Supply in Operation

A fleet’s charge demand refers to the electricity required for all operations, considering each route’s start and stop points, cargo, road conditions, year-round weather (e.g., extreme temperatures), peak operational moments, and the need for on-route charging on longer routes.

Charge supply includes the available charge power and capacity from the fleet’s own charge locations, secondary sites with excess capacity, frequently visited stops and destinations, and public charging networks. To effectively integrate these options into a fleet’s charge strategy, it is essential to know each option’s predicted, dynamic pricing and access windows.

Application: Delivery Fleet Operating from a Depot

Applying this to a delivery fleet means you need to be able to predict the energy needed for each route for each vehicle, translate that into the required charge level, and calculate the optimal charge strategy based on the fleet’s charge window and predicted electricity prices. This approach results in a lean charge strategy that avoids overcharging, allows vehicles to share chargers, and optimizes cost based on dynamic electricity pricing. But the journey doesn’t end there.

As your electric fleet evolves, new challenges emerge. Longer routes require strategic on-route charging, necessitating sophisticated charge point recommendations. Fleet expansion demands rigorous simulations using historical data to determine the optimal mix of vehicle types, battery configurations, and charging infrastructure to avoid overinvestments.

At some point, many organizations will face grid limitations, presenting significant hurdles. Solutions range from upgrading existing connections to decentralizing charge locations — or even generating power independently and creating a local shared grid. Each option has trade-offs between operational flexibility, energy-supply reliability, CAPEX, operating costs, and revenue growth.

It doesn’t matter the type of commercial vehicle fleet or what phase you are in with electrifying it; your ability to balance your charge demand and charge supply will determine your operational costs.

Keep in mind that accounting for a disbalance drives up costs and complexity: it results in overinvestment and stacking safety buffer on safety buffer. So the optimization points for running a lean, mean commercial EV fleet are found in that balance. That’s why we call it a “mantra.”

A Technology Stack Open to Integration

A fleet’s ability to match supply and demand depends on its capability to predict its charge supply and demand. This requires integrating various technologies, including:

-

Logistics and operations

-

Transportation management

-

Energy management

-

Depot charge management

-

Predictive energy consumption

-

On-route charge station recommendations

-

Real-time vehicle data

-

Charge-pricing data

No single company can provide all these solutions. Integration of multiple providers’ technologies is key to creating a fleet-specific predictive stack.

The Charging & Driving Process

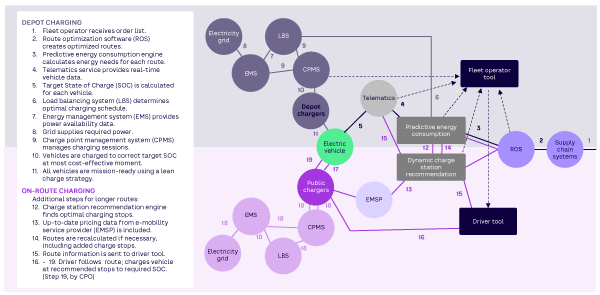

Figure 2 shows the technologies needed for charging and driving commercial vehicles from a depot, on longer routes, and when unexpected situations require dynamic rerouting. It also outlines all the steps and interactions between the various technologies:

-

Depot charging a delivery fleet. The process starts with charging all vehicles at the depot.

-

Driving long routes with on-route charging. Steps 1 to 5 remain the same. Steps 12 to 20 are added, whereas Step 19 is done by the charge point operator (CPO) and is beyond the control of the fleet or driver.

-

Dynamic rerouting a delivery fleet. The combination of real-time telemetry, a predictive energy-consumption engine, and a charge station recommendation engine enable dynamic rerouting of an EV. The use case for this is offering drivers a seamless contingency plan should anything not go according to plan on a route, such as an unexpected detour.

-

Fleet operator and driver tool. Dashed arrows indicate the technologies “feeding” the apps that the fleet operator uses to orchestrate/monitor the fleet and that the driver uses to execute the mission.

Future-Proofing a Fleet’s Tech Stack

The ICE ecosystem has matured over a century, but the (commercial) EV and charging landscape is in its infancy. Today’s EV operations require integrating various technologies to achieve efficiency.

Creating an adaptable, integration-ready technology foundation is the key to future-proofing fleet operations. This strategy allows for the seamless addition of functionalities or upgrades to existing systems as advancements occur, ensuring long-term operational efficiency and competitive advantage.

One Size Won’t Fit All

Energy supply varies by location, and fleets differ in purpose, size, and operating context. This reality demands a flexible, bottom-up approach to electrification. Success lies in:

-

Leveraging historical fleet data for accurate simulation

-

Incorporating site-specific electricity supply information

-

Customizing hardware configurations for each fleet and location

Although a core technology stack (including route optimization, consumption prediction, station recommendation, telematics, and charge management systems) can be shared across fleet segments, it’s crucial to maintain flexibility. An agnostic, integration-friendly approach prevents vendor lock-in and allows seamless incorporation of new technologies.

Integration Strategy

Fleet electrification parallels digital transformation in other industries. Three typical approaches are:

-

Best in class — integrating and combining top solutions for each function

-

Single vendor — opting for a ready-made, all-in-one solution

-

Integrator — employing a third party to blend various vendor solutions

Each strategy has benefits in terms of flexibility, control, and resource requirements. The optimal choice depends on an organization’s needs, capabilities, and long-term vision.

Conclusion

The large-scale electrification of commercial vehicles presents significant challenges due to the highly optimized, low-margin nature of logistics and distribution systems. The fundamental difference between using fossil fuels and electricity for operations lies in energy storage and availability.

Fossil fuels allow for easy storage of large amounts of energy; electricity storage is limited and expensive. This means electric fleets must rely on the local grid’s capacity and availability, which can vary.

To overcome these challenges and make electrification efficient, intelligent and flexible digital solutions are needed. These guiding principles are crucial for scaling and future-proofing an electrified fleet:

-

Match supply and demand. Balance charge supply (access to charging and battery capacity) with charge demand (energy needed for operations).

-

Develop an open technology stack. Integrate a variety of technologies to predict charge supply and demand, including supply chain, energy system, depot charging, vehicle, predictive range, on-route charging, and transportation management systems.

-

Adopt a flexible approach. Recognize that one size doesn’t fit all due to varying energy supply conditions at different locations. A bottom-up approach to electrification is necessary for efficiency.

By adhering to these principles and leveraging digital solutions, companies can take advantage of electricity’s benefits, including lower costs, less environmental impact, improved user experience, reduced pollution, and new operating models.

References

1 Bohnsack, René, Christina M. Bidmon, and Jonatan Pinkse. “Sustainability in the Digital Age: Intended and Unintended Consequences of Digital Technologies for Sustainable Development.” Business Strategy and the Environment, Vol. 31, No. 2, December 2021.

2 Falcke, Lukas, et al. “Digital Sustainability Strategies: Digitally Enable and Digital-First Innovation for Net Zero.” Academy of Management Perspectives, March 2024.

3 “CO2 Emissions from Road Traffic Up by Nearly Three Percent in 2022.” Statistics Netherlands (CBS), 15 April 2024.

4 “Motor Vehicles; Type Age Class, 1 January 2000–2022.” CBS, 12 August 2022.

5 CBS (see 3).

6 Ruiz, Pablo. “Stadsbussen in de EU: Elektrische Bus Haalt Dieselbus in” (“City Buses in the EU: Electric Bus Overtakes Diesel Bus“). Rabobank, 5 April 2023.

7 Hoekstra, Auke. “The Underestimated Potential of Battery Electric Vehicles to Reduce Emission.” Joule, Vol. 3, No. 6, June 2019.

8 “Negative Electricity Prices: Challenges & Solutions for Renewable Energy Producers.” Withthegrid, accessed October 2024.

9 Diaz, Carlos. “Five Ways to Solve Last Mile Problems in 2024.” Netlogistik, 29 December 2021.

10 “Netherlands Last Mile Delivery Market Size & Share Analysis — Growth Trends & Forecasts (2024–2029).” Mordor Intelligence, accessed October 2024.

11 Plazier, Paul, et al. “Towards Sustainable Last-Mile Logistics? Investigating the Role of Cooperation, Regulation, and Innovation in Scenarios for 2035.” Research in Transportation Business and Management, Vol. 56, No. 101198, 2024.

12 Mortensen, Kristian Kaas. “Digital Challenges for the European Trucking Industry.” Trans.Info, 9 October 2020.