AMPLIFY VOL. 37, NO. 6

In recent research from The Economist, 63% of executives named macroeconomic uncertainty and geopolitics as major supply chain disruptors.1 Other reports have found that supply chain disruptions are a drag on global activity and trade (including difficulties in the logistics and transportation sector and product shortages), have a negative impact on global production, and contribute to inflation.2

The volatile geopolitical landscape (Red Sea shipping disruptions, the Russia-Ukraine war, the Israel-Hamas war, and various economic trade wars), combined with the increasingly evident effect of climate change, is wreaking havoc on regional and global agri-food supply chains. Agri-food supply chain disruptions are no longer confined to farmers and food distributors — they can have serious repercussions in areas critical to the well-being of economies and societies in both developed and developing countries. For example, the Russia-Ukraine war is impacting global wheat, sunflower oil, and maize supplies, as well as food security and aid.3

In response, organizations and governments are looking at ways to leverage AI to safeguard and enable agri-food supply chain resilience. In this article, supply chain resilience refers to the ability to prepare and respond to disruptions, make a timely and cost-effective recovery, and calibrate to a post-disruption state (ideally, a better state than prior to the disruption).4

Resilience consists of four dimensions:5,6

-

Readiness — an organization’s anticipation of a disruption, either by preparing for it or avoiding it.

-

Responsiveness — preplanned elements that mitigate the impact of a disruption while allowing the system to remain functional.

-

Recovery — repair of loss and the minimization of the time it takes to return to the original or desired state.

-

Adaptability — the capability to adapt to any operating changes in the environment.

In the context of agri-food supply chains, AI has the power to enable resilience by enhancing risk management and predictive analytics, enabling real-time decision-making and adaptability, automating problem-solving, and supporting long-term strategic planning.7

AI-Powered Resilience in Agri-Food Supply Chains

AI can be applied to various elements of the supply chain, including forecasting, process and procedure optimization, supplier selection and evaluation, and automation and decision support for configuration, design, and planning.8

AI-powered systems provide organizations with the ability to process large, complex data sets in real time to enhance forecasting accuracy. Other benefits of AI-powered supply chain systems include real-time production tracking, prevention of order shipment delays, process optimization, and customer product prediction.9

Supply chain resilience also builds on elements of the smart factory, including the supplier quality management system, real-time data exchange, and predictive analytics to enable data-driven insights and actions.10 Supply chain resilience requires proactive, prescriptive, guided risk mitigation, which involves organizational agility, rapid turnaround time to respond to planned and unplanned events, and flexible and dynamic connections between stakeholders in the supply chain ecosystem.

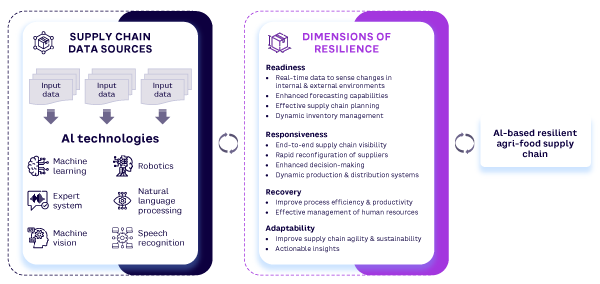

Our data analysis found that AI technologies can enhance each dimension of resilience to enable resilience in agri-food supply chains. In summary:

-

Readiness. AI enables real-time data sharing, enhancing forecasting capabilities and enabling effective supply chain planning and dynamic inventory management.

-

Responsiveness. AI-powered supply chain management tools support rapid reconfiguration of suppliers.

-

Recovery. AI facilitates the effective management of human resources and improves process efficiency and productivity.

-

Adaptability. AI improves the agility and sustainability of supply chains by providing actionable insights.

AI is increasingly being used by organizations for the procurement of short-term workers, which in turn increases resilience as supply chain managers seek innovative ways to mitigate the looming labor shortage.11,12

AI can also be leveraged to improve employee safety by using machine vision to monitor the use of personal protective equipment and verify that employees are adhering to the company’s health and safety protocols and industry-wide standards. Companies can also use AI to process data from systems aboard company vehicles to monitor whether drivers are operating them safely.13 AI can enhance adaptability by providing logistical solutions to minimize shipment lead times by coordinating important shipping documents, determining any missing documentation, and recommending actions to avoid risks proactively.14

Research Methodology

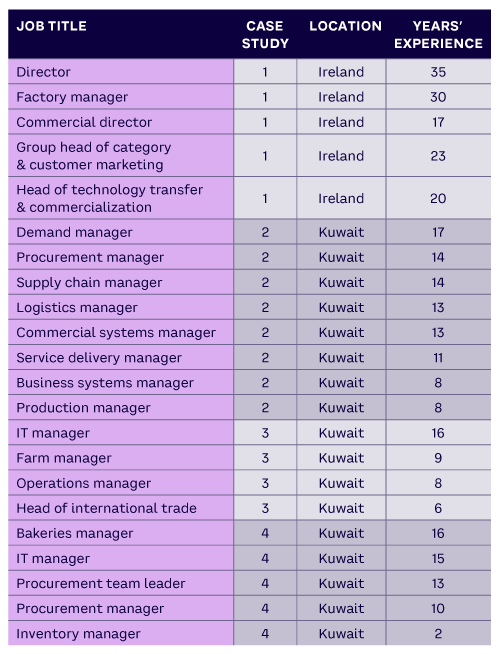

This article is informed by insights from practitioners at four agri-food companies located in Ireland and Kuwait that operate in large, complex regional and global supply chains. We also draw on secondary data sources (industry reports, academic articles). A description of the companies is provided below, and the profile of practitioners is presented in Table 1. Primary data collection included face-to-face interviews with a focus on understanding how the case study companies use AI technology to enable resilience in agri-food supply chains in their respective industry.

Case Study 1

This indigenous Irish company serving international markets is one of Europe’s largest meat groups. It has annual earnings of more than US $2 billion, employs more than 5,000 people, and works with more than 28,000 farmers. The company has 14 manufacturing facilities throughout Ireland and the UK; sales offices in Europe, the US, Asia, and Africa; and a presence in more than 43 countries.

The group processes more than 50,000 tonnes of meat annually, including 500,000 cattle, 1.7 million lambs, and 450,000 pigs. As a primarily B2B company, it offers a broad range of fresh and value-added meat products serving the food service and retail markets. The company has a portfolio of brands that are successful in the chilled convenience and frozen meat categories in various markets.

Case Study 2

In operation for more than 75 years, this Kuwaiti company operates a vertically integrated business model encompassing food manufacturing, distribution, retail, wholesale, and contract services. It has operations in five other countries (Saudi Arabia, United Arab Emirates, Qatar, Jordan, and Iraq). It imports international brands into Kuwait and produces various Kuwaiti-based food brands. The company employs more than 8,800 in its food business and healthcare/consumer business combined. The food business line accounts for 69% of the company’s total revenue, exceeding $582 million in 2023.

Case Study 3

Established in 1973 in Kuwait, this company manages a fleet of giant ships for trading and transporting livestock and several types of meat for the local market and international exports. The company owns the largest feedlot in the world, with a capacity of 200,000 heads, and its factory is considered one of the most advanced meat-processing capabilities in Kuwait. The company has subsidiary units in the United Arab Emirates, Australia, and South Africa. It produces organic fertilizers that guarantee high-quality green vegetation for its livestock. The company recently achieved $70 million in annual revenue.

Case Study 4

Established in 1961 in Kuwait, this company owns factories making macaroni, biscuits, vegetable oils, animal feed, and gluten-free products. It operates nine major bakeries located throughout Kuwait that provide high-quality products at competitive prices. It has two production lines that can produce 14,000 loaves of bread in one hour. Its net profit in 2023 exceeded $250 million, a 48% increase compared to 2022. The company employs just under 4,000 people.

Insights from Practice

Each of the companies in our case studies applied several AI-based technologies to enhance resilience in their supply chains, which led to improved performance. For example, case study 1 used robotic process automation to perform repetitive administrative tasks in place of human workers. It eliminated more than 15,000 hours per year of tasks related to supply chain management, increasing resilience.

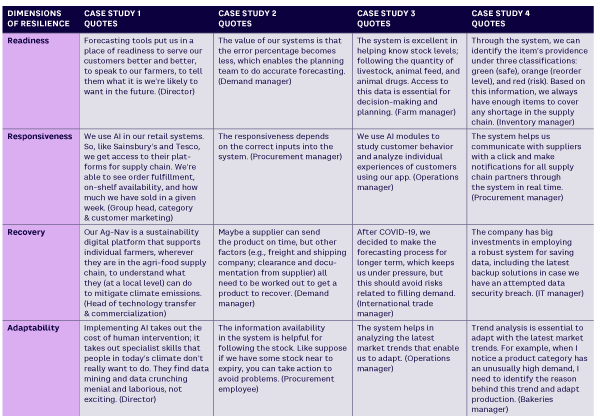

Case studies 2, 3, and 4 all used expert systems (i.e., SAP HANA, Oracle, ERP [enterprise resource planning], warehouse management) to simulate human problem-solving and create advanced planning solutions to optimize sales, develop dynamic forecasting processes, elevate operational planning in the supply chain, and improve relationships with suppliers and customers. Drawing on the insights provided by the practitioners, Table 2 shows how AI-based technologies enhance the four resilience dimensions.

In Figure 1, we conceptualize how AI technologies (i.e., machine learning, expert systems, machine vision, robotics, natural language processing, speech recognition) can be used in agri-food supply chains and how they can enhance resilience dimensions.

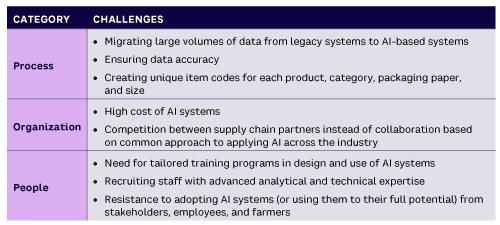

In addition to describing the benefits of AI in this context, the practitioners acknowledged that digitizing their supply chains using AI technologies was challenging (see Table 3).

Looking Forward

The global agri-food sector expanded from $8.28 trillion in 2021 to $8.67 trillion in 2022 and is projected to reach $12 trillion by 2027.15

The threat of further supply chain disruptions is likely, especially if geopolitical uncertainty and repositioning intensify in the coming months, and there is a high probability the market value of this sector will erode. However, such events should be viewed by business leaders and governments as an opportunity to redesign their supply chains with a future resilience mindset.

As the agri-food sector grapples with geopolitical tensions, population growth, technological advancements, and shifting consumer preferences, increased collaboration between industry, public sector entities, and academic researcher will be key to building both resilient supply chains and economies. As such, governments can no longer take a back seat role and simply wait for markets to fail before implementing interventions. Against this background and the increasing digitization of agri-food supply chains, the ability of organizations to adopt, adapt, and effectively use AI is more critical than ever.

References

1 “Next-Gen Supply Chains: Navigating Uncertainty and Generative AI.” Economist Impact/GEP, accessed June 2024.

2 Attinasi, Maria Grazia, et al. “Supply Chain Disruptions and the Effects on the Global Economy.” European Central Bank (ECB) Economic Bulletin, Issue 8, 2021.

3 Woodburn, Daniel, and Emily Sample. “Cascading Fragility: From Ukraine to the World.” In “Fragile States Index,” edited by Ediye Bassey. The Fund for Peace (FFP), 2023.

4 Tukamuhabwa, Benjamin R., et al. “Supply Chain Resilience: Definition, Review and Theoretical Foundations for Further Study.” International Journal of Production Research, Vol. 53, No. 18, April 2015.

5 Ali, Imran, et al. “Reimagining Global Food Value Chains Through Effective Resilience to COVID-19 Shocks and Similar Future Events: A Dynamic Capability Perspective.” Journal of Business Research, Vol. 141, March 2022.

6 Stone, Jamie, and Shahin Rahimifard. “Resilience in Agri-Food Supply Chains: A Critical Analysis of the Literature and Synthesis of a Novel Framework.” Supply Chain Management, Vol. 23, No. 3, June 2018.

7 Smyth, Conn, et al. “Leveraging Artificial Intelligence to Enhance Supply Chain Resilience: Insights from the Agri-Food Industry.” Amplify, Vol. 37, No. 5, 2024.

8 Smyth, Conn, et al. “Artificial Intelligence and Prescriptive Analytics for Supply Chain Resilience: A Systematic Literature Review and Research Agenda.” International Journal of Production Research, April 2024.

9 Colehower, Jonathan. “Using Technology to Improve Supply-Chain Resilience.” Harvard Business Review, 25 September 2023.

10 Fosso Wamba, Samuel, et al. “Industry Experiences of Artificial Intelligence (AI): Benefits and Challenges in Operations and Supply Chain Management.” Production Planning & Control, Vol. 33, No. 16, April 2021.

11 IBM Consulting. “Artificial Intelligence and a New Era of Human Resources.” IBM, 9 October 2023.

12 Cassidy, Francesca. “2024 Supply Chain Trends: Resilience Amid Chaos.” Raconteur, 14 December 2024.

13 Tsidulko, Joseph. “Benefits of AI in the Supply Chain.” Oracle, 11 January 2024.

14 Jackson, Ilya, et al. “Generative Artificial Intelligence in Supply Chain and Operations Management: A Capability-Based Framework for Analysis and Implementation.” International Journal of Production Research, January 2024.

15 “2023 Global Trends Influencing Agribusiness and Market Dynamics.” AgroSpectrum, 22 September 2023.